Nano Foam Concrete

Sun Guo Xing, Liang Rui

University of Macau

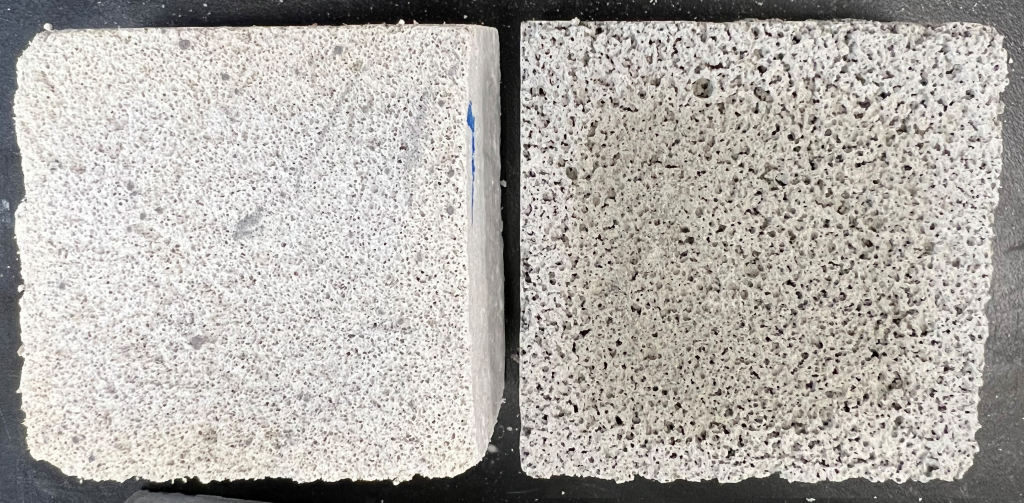

In the invention, the nanoparticles are aggregated on the boundaries of the bubble, and then the foam is mixed with the cement slurry to obtain the nano-foam concrete material with the pores much smaller than that of the market product in the same formula. Compared with similar products on the market, it can save 15-40% of cement and other raw materials at the same strength. While improving the building's thermal insulation capacity, it also reduces the corresponding carbon emissions. It can be used to produce lightweight building materials such as foam concrete wall panels, fire door core panels, etc. In the field of cast-in-place backfilling of large-scale construction projects, the product has been successfully applied to many key projects in Mainland China, such as the backfilling of buildings in Zhuhai High-tech Zone, Zhuhai-Macao Hengqin Port Integrated Transportation Hub, Xiangyang East-West Axis Road Project, and will soon be applied to the fourth Macau-Taipa cross-sea bridge, the bridge connecting the University of Macau to the Hengqin port, and other Macau projects. The total application amount has reached 60,000 cubic meters, saving 10,000 tons of cement and reducing corresponding carbon emissions by 9,000 tons. It is rapidly being introduced to the national market.

Fig 1 Comparison of pore size between nano-foamed concrete (left) and commercial foamed concrete (right) under the same formulation conditions.

Fig 2 Construction scene of nanofoam concrete cast-in-place backfill: sprayed nanofoam (left), nanofoam concrete pouring (middle), finished building surface (right).