Preparation of High-Performance Hydrogels from Cement-Based Sustained-Release Nanoparticles

Sun Guo Xing, Liang Rui, Li Zong Jin

University of Macau

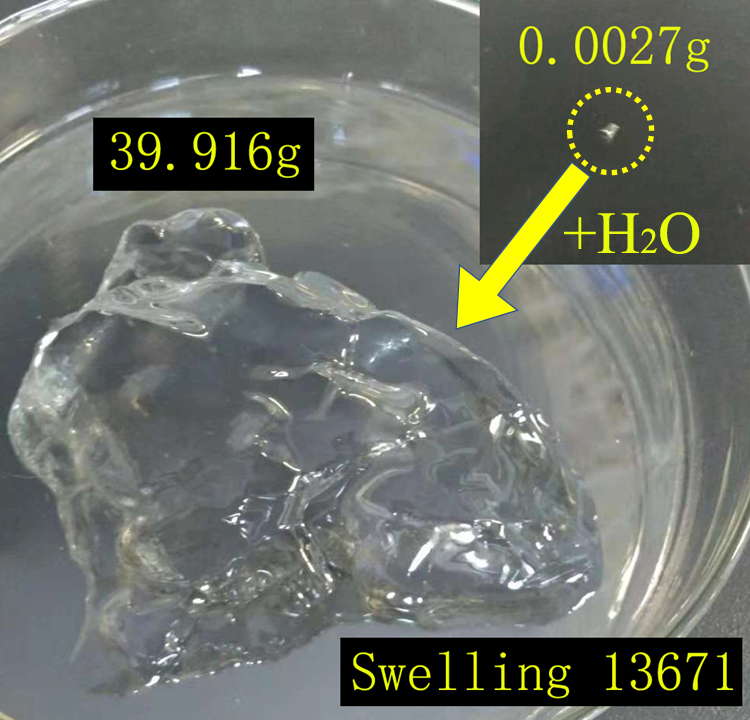

This project is the first to identify a novel method for producing calcium hydroxide particles with diameters under 5 nanometers by immersing Ordinary Portland Cement in 0°C cold water. This process induces the gradual release of uniformly dispersed nanoparticles from the cement surface, offering the most cost-effective solution for large-scale nanoparticle production to date. The resulting nanoparticles markedly improve the mechanical properties, water absorption, and swelling behavior of standard hydrogels, even at low concentrations (0.02 wt%). (1) The tensile strength of hydrogels increased from 20 kPa to 630kPa, and the tensile ratio improved from 10 times (irreversible deformation) to 121 times (reversible deformation). The material is capable of withstanding pressures of up to 100 MPa and instantly returning to its original shape. Additionally, the cost of this elastomeric material is only 60% of that of silicone alternatives, and it is being used in the development of simulated robot skin for two companies in Guangdong. (2) The nanoparticles can also be used to create a super-absorbent gel material, capable of absorbing up to 13,671 times its own weight in pure water. When incorporated at just 0.012 wt% into soil with 40% moisture content, this material retains moisture for up to six months without leakage, loss or soil compaction, offering a sustainable solution for agricultural water retention. Furthermore, it serves as an effective curing agent in concrete, improving the anti-cracking properties of large-scale construction materials. Compared to commercially available internal curing agents, this material's expansion ratio in cement slurry is 4-5 times higher, resulting in a fourfold reduction in concrete shrinkage, with only 50% of the strength loss observed in commercially available products. This product has been successfully employed in the preparation of large concrete components and in on-site casting for Hengqin Port construction project.

Fig 1 A grain of Ordinary Portland Cement releases a large quantity of uniformly dispersed calcium hydroxide nanoparticles, each with a three-dimensional size under 5 nm in cold water at 0°C. This process represents the most economical method for large-scale nanoparticle production.

Fig 2 The addition of just 0.02 wt% of cement-released calcium hydroxide nanoparticles allows polyacrylamide hydrogel to instantly recover after withstanding pressures up to 100MPa (left), making it suitable for highly elastic simulated skin applications. The expansion ratio of polyacrylate water-absorbent resin is also enhanced to 13,671 times its own weight (right), demonstrating its potential in soil moisture retention and large-scale concrete curing applications.